BACKGROUND

With globalisation, the demand for Heavy Duty Shipping Sacks (HDSS) has increased significantly. Typically, HDSS is purposefully structured for superior performance to facilitate and protect goods in various environments during logistics and handling. Used HDSS are very good base material for recycling after usage.

CHALLENGE

As part of its commitment to create sustainable packaging solutions for a circular economy, Borouge has identified the area of polyethylene-based HDSS solutions to be a target for incorporating post-consumer recycled content without compromising performance. Based on the requirements of the application, the mechanical properties of the HDSS material have to remain robust with high performance to meet its service life requirement. To enable circularity for the packaging, recycled polyolefins incorporated to the new material need to deliver equal performance and quality to meet the stringent requirements for HDSS.

SOLUTION

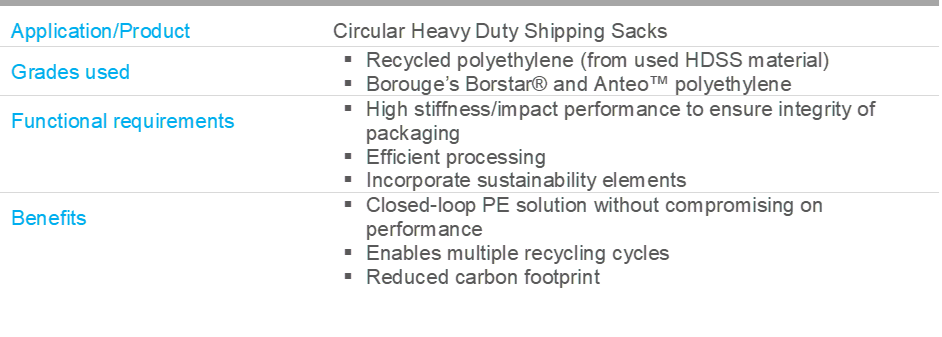

In close collaboration with leading value chain partners comprising a recycling company, convertor, and a machine supplier, Borouge successfully developed a closed-loop solution with post-consumer recycled (PCR) polyethylene for Heavy Duty Shipping Sacks. The solution incorporates 30% recycled content from used polyethylene (PE) HDSS and is boosted by Borouge’s Borstar® and Anteo™ enhanced PE grades. Used HDSS material is recovered through dedicated waste streams, and goes through an advanced mechanical recycling process. The recycled PE resins are then subjected to stringent material qualification before being incorporated with virgin PE to the end application for customer’s validation – to ensure that the packaging integrity and its performance are fulfilled. Processing efficiency is achieved through Borouge’s extensive experience and technical know-how leading to formulations with booster grades from Borstar® and Anteo™ PE portfolio. The addition of the differentiated booster grades enable good processability without any major modifications during blown film and Form Fill Seal (FFS) packaging operations. The result is a circular packaging solution that offers a balance of high stiffness and impact performance, excellent sealing properties and efficient process efficiency, at a distinctively lower carbon footprint.

LIFE CYCLE ASSESSMENT

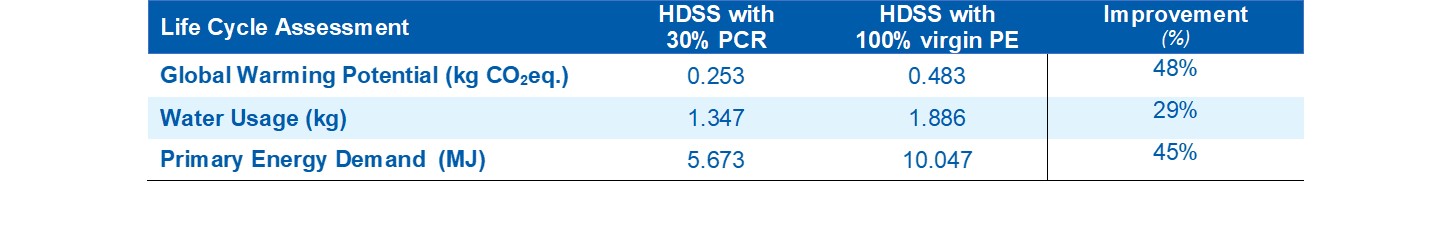

With the successful implementation of the closed-loop solution for Heavy Duty Shipping Sacks, this pioneer initiative led to an achieved carbon footprint reduction with recycled content. To determine the environmental impact of the Circular HDSS packaging, a ‘cradle to grave’ life cycle assessment (LCA) was conducted through accredited, independent third-party testing body, TÜV Rheinland (TUV). The LCA was conducted based on ISO14067, which certifies the carbon footprint of products, using the GaBi (10.6.2.9) software and database for its comprehensive assessment. The certification assesses the product’s entire life-cycle, validating the reduction of carbon emissions and energy consumption, with reliability and transparency. The Circular HDSS (made with 30% PCR PE) and HDSS produced with 100% virgin PE were assessed, with verification being done at the sites of the recycling company and convertor.

Based on the assessment, the findings showed a significant reduction in carbon emissions for the HDSS made with 30% PCR – leading to an improvement of 48% in Global Warming Potential, energy consumption reduced by 45%, with water savings of almost 30%. The results validate the efforts to innovate products using mechanically recycled content, without compromising on the packaging performance and integrity. With Borouge’s Global Recycled Standards (GRS) certified recycled polyolefins, such solutions enable the value chain and customers to fulfil their sustainability pledges and targets in their products. This pioneer initiative to develop a closed-loop solution for Heavy Duty Shipping Sacks by Borouge and its valued partners paves the way for the transformation towards circularity for more sustainable packaging applications.

SUMMARY