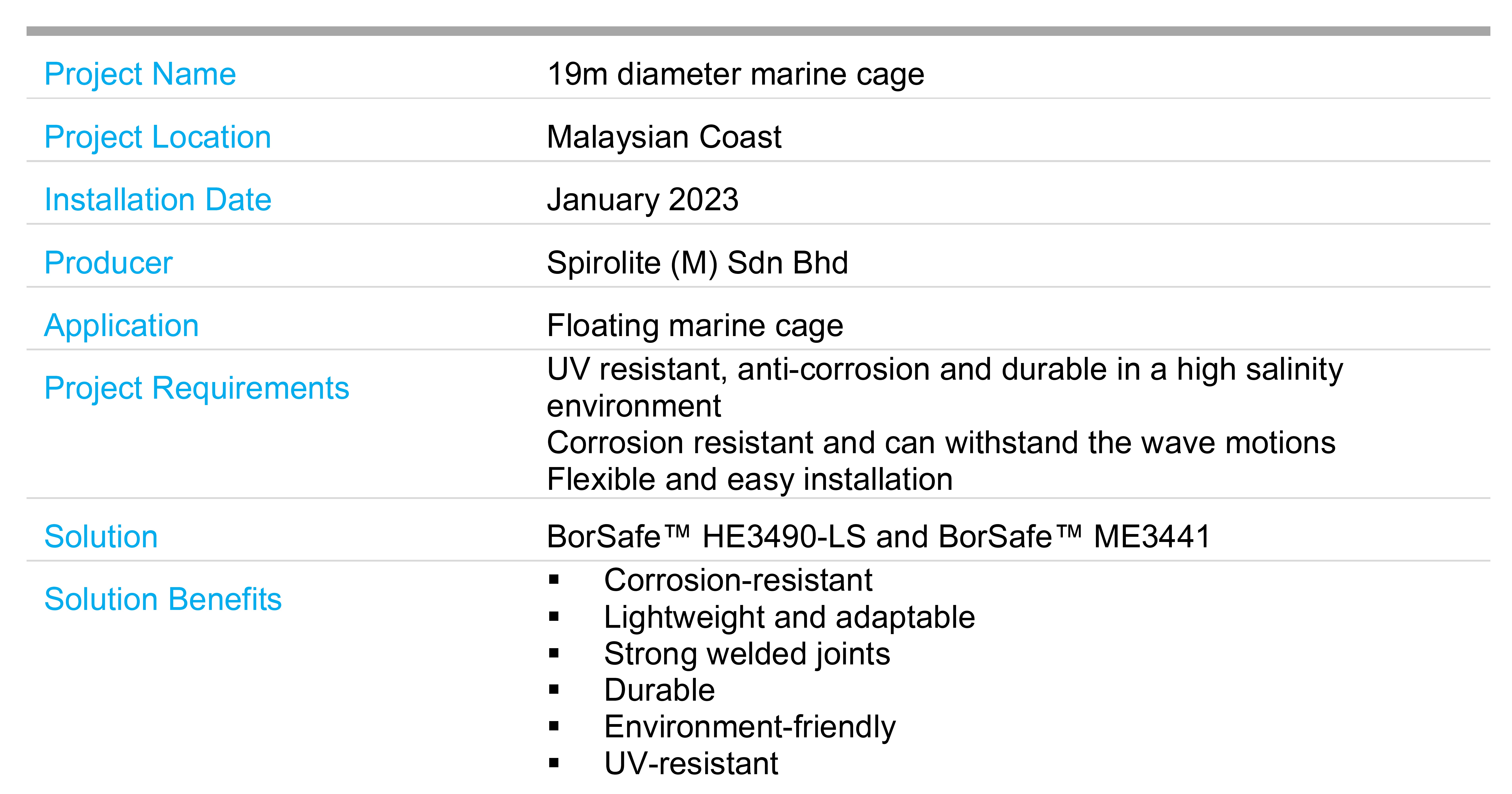

BACKGROUND

Aquaculture, also known as aquafarming, is the cultivation of aquatic organisms including fish, shellfish, crustaceans and aquatic plants under controlled environments. This farming practice involves various techniques and methods to rear, breed and harvest these organisms in freshwater or saltwater environments, such as ponds, tanks, cages or raceways.

Aquaculture is crucial to Malaysia's food security and economic development, as the government recognises it as a key growth sector with the capacity to bolster food supply and drive economic progress. When compared to other agricultural sectors, such as oil palm, rubber, paddy, fruits, and vegetables, aquaculture stands out as highly productive in terms of both income per hectare per annum and return on investment.

In the past five years, Malaysia’s aquaculture sector has experienced an approximate annual growth rate of 10 percent.1

Traditional fish breeding uses simple wooden and tin pontoon net cages, which can be poor in resistance to wind and waves, limiting their use in rough conditions. Their short lifespan due to material degradation necessitated frequent costly repairs or replacements. These cages also had limited cultivation capacity due to their size and stability, capping each operation's productivity.

“What we would like the children to do is to share the knowledge with their family and friends so they can spread the importance of looking after our environment,” she added.

At the same time, the Malaysian aquaculture sector faces several challenges, each with potentially detrimental effects on the environment and the industry's long-term growth:

- Overfishing: Reduces wild fish numbers and may lead to fish stock collapse, disturbing marine biodiversity and environmental health

- Limited land: Intensifies competition for coastal areas among different industries, causing conflicts, unsustainable practices, habitat loss, and environmental damage.

- Climate change: Increases severe weather frequency, damaging traditional fish cages, resulting in economic loss, higher resource use, and negative environmental impacts.

SOLUTION

Spirolite (M) Sdn Bhd is a leading Malaysian manufacturer specialising in polyethylene piping and related products. With a focus on innovation and quality, Spirolite offers a wide range of solutions for various industries, including water, sewer, telecommunications and aquaculture.

To address the challenges faced by farmers in the aquaculture sector, Spirolite developed a robust and long-lasting marine cage, constructed from polyethylene parts. The marine cage is specifically designed to withstand the rigours of the marine environment, offering a sustainable and efficient solution for modern aquaculture operations.

The marine cage can also address some of the industry issues in the following ways:

- Mitigates overfishing by facilitating a consistent, sustainable alternative to wild-caught seafood through the cultivation of various aquatic species, thereby minimising bycatch

- Allows for efficient use of marine space without competing with terrestrial land uses as it can be situated in offshore or deep-water locations, which are often underutilised

- Improves water quality by reducing the discharge of waste products into the surrounding environment. This can contribute to alleviating the negative impacts of climate change, such as ocean acidification and deoxygenation

As both the floating pipes and handrails of the marine cages will be installed on sea level with high salinity and constant tidal wave movement, the materials chosen must be corrosion resistant, easy to install, and can withstand wave motions.

Spirolite chose Borouge's BorSafe™ HE3490-LS and BorSafe™ ME3441 materials due to their exceptional mechanical and physical properties for this project. The black polyethylene floater pipe of the marine cages is made of HE3490-LS, while the yellow coloured ME3441 is employed in the marine cage's handrails to enhance visibility at night.

The advantages of the polyethylene marine cage, made with BorSafe™ HE3490-LS and ME3441, include:

- Resistance to corrosion, making them ideal for seawater environment application

- Lightweight and adaptable, suitable for challenging installation conditions in the sea

- Good flexibility and strong welded joints to adapt to undersea conditions and wave movements

- Enhanced durability, characterised by prolonged performance and minimal maintenance needs

- Lower environmental impact due to full recyclability after the end of its service life

Furthermore, pre-compounded BorSafe™ HE3490-LS pipes have good UV resistance, ensuring a 15-year service life, as opposed to wooden cages requiring maintenance and replacement every five to 10 years.

By carefully selecting solutions that can address the industry’s unique requirements, both marine cage manufacturers and farmers can rely on the durable and robust infrastructure that supports the expansion of a resilient aquaculture industry.

Borouge's innovative solutions offer materials that adhere to stringent standards, advocating for an industry with greater longevity and efficiency. By utilising these solutions, Borouge's customers can advance their commitment to environmental stewardship, strengthening their competitiveness in a market that is growing ever more conscious of environmental concerns.

1 © FAO 2023. Malaysia. Text by Mazuki Hashim. Fisheries and Aquaculture Division [online]. Rome. [Cited Friday, May 5th 2023].

https://www.fao.org/fishery/en/countrysector/my/en

Close-up of Spirolite’s 19m diameter floating marine cage along the Malaysian Coast

Photo courtesy of Spirolite (M) Sdn Bhd